Waygate Krautkramer USM100 Flaw Detector

November 12, 2021

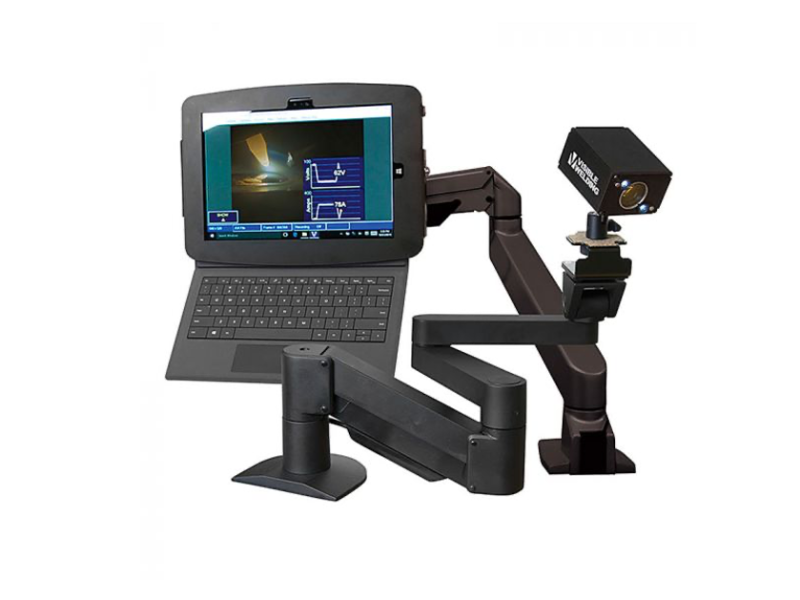

Cavitar C400-H Welding Camera System

April 29, 2023Cavitar C400-H Portable Welding Camera System

The Cavitar C400-H Welding Camera System is a complete, compact ready-to-use weld visualization solution that includes a camera, integrated laser illumination, and optics adjustable to almost any welding application. The C400-H uses cutting-edge technology combined with laser illumination to handle the intense light from a welding arc. Easy to set up and versatile, this weld monitoring system is suitable for quality assurance, machine vision, and welding research applications.

The Cavitar C400-H Welding Camera System is a complete, compact ready-to-use weld visualization solution that includes a camera, integrated laser illumination, and optics adjustable to almost any welding application. The C400-H uses cutting-edge technology combined with laser illumination to handle the intense light from a welding arc. Easy to set up and versatile, this weld monitoring system is suitable for quality assurance, machine vision, and welding research applications

The Cavitar Welding Camera delivers clear, high-resolution images of various popular welding techniques such as GMAW (MIG, MAG) and GTAW (TIG). It also handles all major beam welding processes, including CO2 laser, fiber laser, diode laser, Nd:YAG laser, and electron beam techniques.

Use cases include real-time adjustment of welding parameters for automated welding processes such as tube seam welding. At the same time, operators may perform their work at safe distances away from the arc, heat, and dangerous fumes.

The camera’s compact design allows it to be implemented into the most challenging and space-restrictive remote applications. Supplied cooling channels and camera housing heat sinks ensure the survivability of the camera in these harsh environments.

Adjustable optics allow the camera to be attuned in an application-specific implementation, ensuring it is the right welding camera tool for the job.

Details

• Monitor the weld process in remote locations

• Live welding demonstrations for on-site training and sharing on large screens

• Plug-and-play, ultra-high clarity weld viewing camera

• Monochrome image

• 70 fps @ full resolution, max 100 fps

• Integrated laser lighting system

• Cooling system for high-temperature applications

Items Included

- EM13010 – Cavitar C400-H Welding Camera:

- Cavitar Camera Unit (B010)

- Temperature warning unit (D002)

- 24V DC Power Supply (E016)

- 2 m Power Supply Cable (G001)

- 10 m Power Cable (G104)

- 10 m GigE Cable (G076)

- EM18879 – Cooling hose connector with O-ring (M058)

- Hose clamp (K027)

- EM18877 – Plastic spare protective spatter shields (I075)

- Cavitar Capture Software and Operation Manual (L012)

- Hex key (1.5 mm) for working distance screws (K030)

- Robust System Case

- Integrated PC

- 23.8 inch IPS 1920 x 1080, 165Hz built-in Monitor

- Cable Reel

- Keyboard

Specifications

| Description | 4th generation compact welding camera for demanding environments with integrated illumination and cooling channels |

| Main applications | GMAW, TIG, Plasma, Robotic, Additive Manufacturing |

| Signal System | GigE |

| Picture | Monochrome |

| Camera Unit | |

| Max resolution (pixel) | 1440 x 1080 |

| Max frame rate (fps)(1) | 70(2) |

| Working distance (mm) | 150…300 |

| Field of view (mm2): | |

| working distance 150 mm | 28 x 21 |

| working distance 200 mm | 40 x 30 |

| working distance 250 mm | 51 x 38 |

| working distance 300 mm | 62 x 47 |

| Size (WxHxL, mm) | 38 x 48 x 99 |

| Weight (g) | 350 |

| Laser Unit | Integrated |

| Laser wavelength (nm) | 640 |

| Laser class | 3R |

| Camera interface | Gigabit Ethernet |

| Gigabit Ethernet connector | M12, X-coded |

| Power & IO connector | M12 |

| Cooling options | Passive: heatsink, heat conduction Active: air, liquid |

(1) At full resolution, dependent on computer performance

(2) Up to 500 fps with reduced resolution (720 x 540 px) with a high-speed version having a USB3 interface.

All values are approximated. The design working distance is 200 mm.