AMS Smart Test Mini

December 11, 2019

Custom Inspection Machines (Click for Additional Info.)

December 20, 2019AMS Smart Test Pro

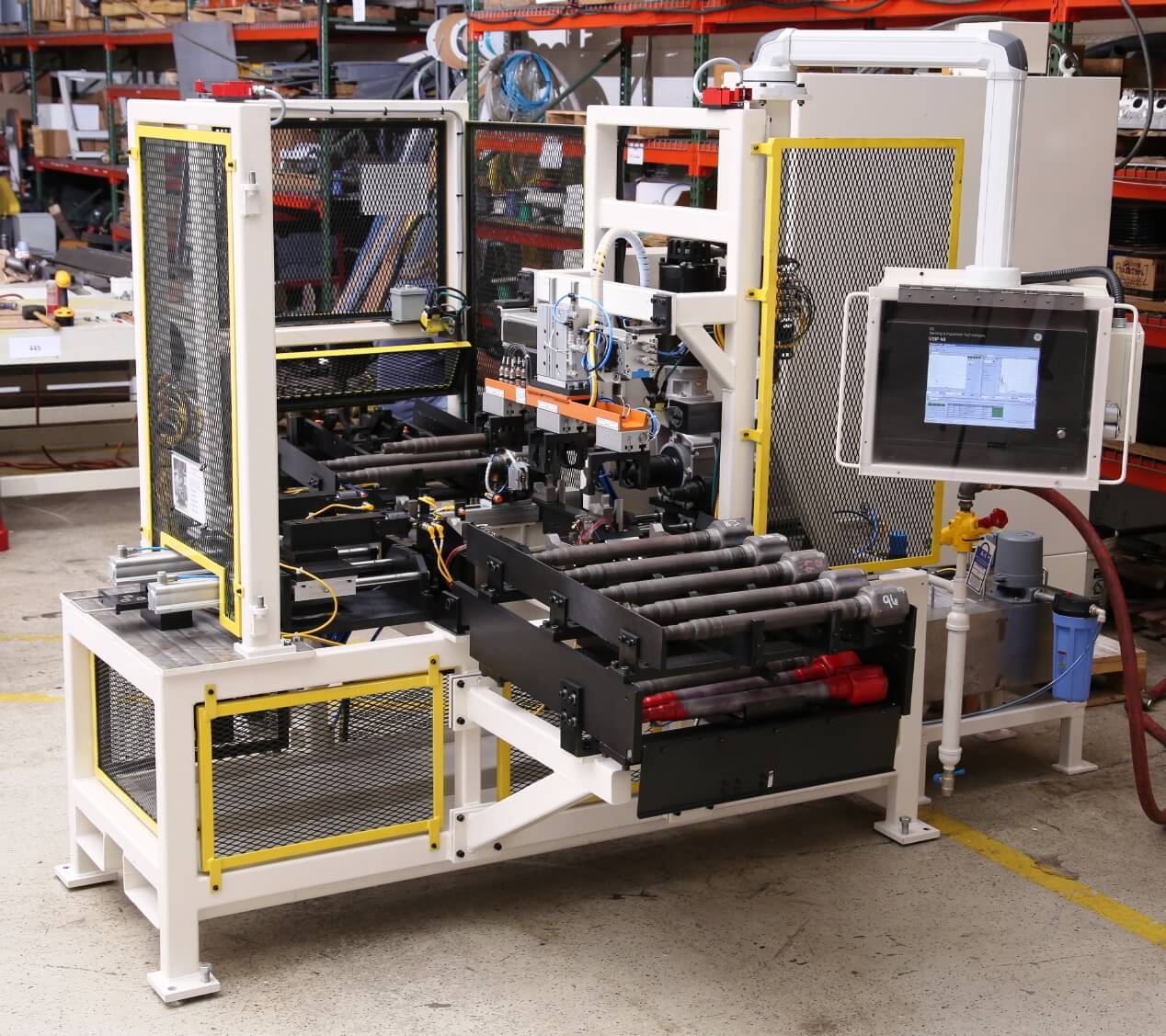

The Smart Test ™ Pro / Pro+ is a high speed, high volume turnkey inspection system intended for 100% inspection on the production floor. Ideal for in-line, automated, objective inspection with no need for operator intervention. The system includes an instrumented spectrum analyzer, turn-key conveyor system, industrial automated electric impactor, microphone, automation accessories (light curtains, PLC, pneumatic ejector), Smart Test ™ ARS software, cables and industrial-grade computer with Microsoft® Excel®.

The Smart Test ™ Pro / Pro+ is a high speed, high volume turnkey inspection system intended for 100% inspection on the production floor. Ideal for in-line, automated, objective inspection with no need for operator intervention. The system includes an instrumented spectrum analyzer, turn-key conveyor system, industrial automated electric impactor, microphone, automation accessories (light curtains, PLC, pneumatic ejector), Smart Test ™ ARS software, cables and industrial-grade computer with Microsoft® Excel®.

Details

Smart Test Family Features:

- Extended bandwidth to 98 kHz – this higher bandwidth enables testing of a much broader range of components, particularly small parts and parts with small features or fine detail.

- Higher resolution – higher resolution provides a much more accurate frequency waveform, meaning a significantly more accurate pass / fail call. This enhances safety and reduces the number of false rejects.

- Ruggedized hardware – engineered with high volume inspection in mind our new spectrum analyzer and industrial electric impactor have been developed to deliver worry free operation under even the most demanding production schedules.

- Smart Test ™ ARS software – our software application has been designed for the shop floor with features that greatly improve productivity and ease of use. Go from part / lot setup to mass production inspection in minutes. Data reporting is simple and intuitive.

- Integral process compensation – provides a quantum leap forward in system reliability for clients who need to accommodate manufacturing process variation. Our integrated solution avoids the need for an external interface and complicated data communication between multiple programs. Downtime is eliminated, productivity, reliability and quality are enhanced.

Specifications