Newage Lab BOSS Brinell Scope

October 19, 2019

Newage NB3010 Brinell System

October 19, 2019Newage PB7000 Brinell System (Discontinued)

The 7000 Series Production Brinell Hardness Testing System applies a high-accuracy load, controlled through a precision load cell operating in a dynamic feedback loop to constantly monitor and control the load. The tester is ideal for those production applications which demand high accuracy and excellent repeatability of load application, along with adjustable time at load and the ability to handle a range of test sample sizes efficiently.

The 7000 Series Production Brinell Hardness Testing System applies a high-accuracy load, controlled through a precision load cell operating in a dynamic feedback loop to constantly monitor and control the load. The tester is ideal for those production applications which demand high accuracy and excellent repeatability of load application, along with adjustable time at load and the ability to handle a range of test sample sizes efficiently.

Details

Features and Benefits:

- Load Cell: The 7000 series of brinell testers uses a load cell to control the load. The load cell has the capability to continually measure and control the force applied to the indenter. This is fed back to the PID microprocessor. This enables precise control of load during ramp up and dwell time. Most large frame brinell unit use pop off valves to control load. Pop off valves are notoriously inconsistent. Once load in achieved the valve opens and oil recirculates to the tank. During dwell time load diminishes and is not maintained. The Newage 7000 has control of the load at all times during the test cycle. We can maintain load to ¼% which four times less than required by ASTM. Pop off valves have a hard time marinating 1%.

- Long Stroke Cylinder & Large Capacity: The 7000 series brinell tester features a long 4” stroke cylinder, other strokes are available upon request. Most brinell testers have little or no stroke and often a small capacity. This means that every time a part is tested it must be raised to the indenter. Once the test is completed it must be brought back down to unload. This is tedious and time consuming. Bad gets worse when there is a mix of part sizes to test. Up down, up down. With the 7000 the long stroke cylinder does the work. The operator places the part on the anvil and cylinder does the work.

- Fabricated Construction: The 7000 is fabricated from 1” steel plate. All joints are bolted and precision doweled for rigidity. This means the 7000 can be made standard or custom size without extensive redesign.

- Standard Purchase Components: The 7000 utilizes standard purchase components for all hydraulic and electronic requirements. Hydraulic and electronic components are from Rexroth and Parker and are typically off the shelf items.

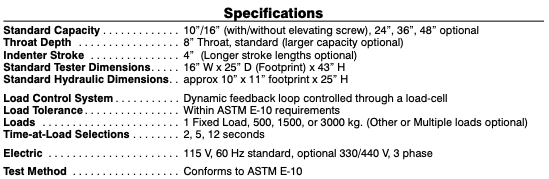

Specifications