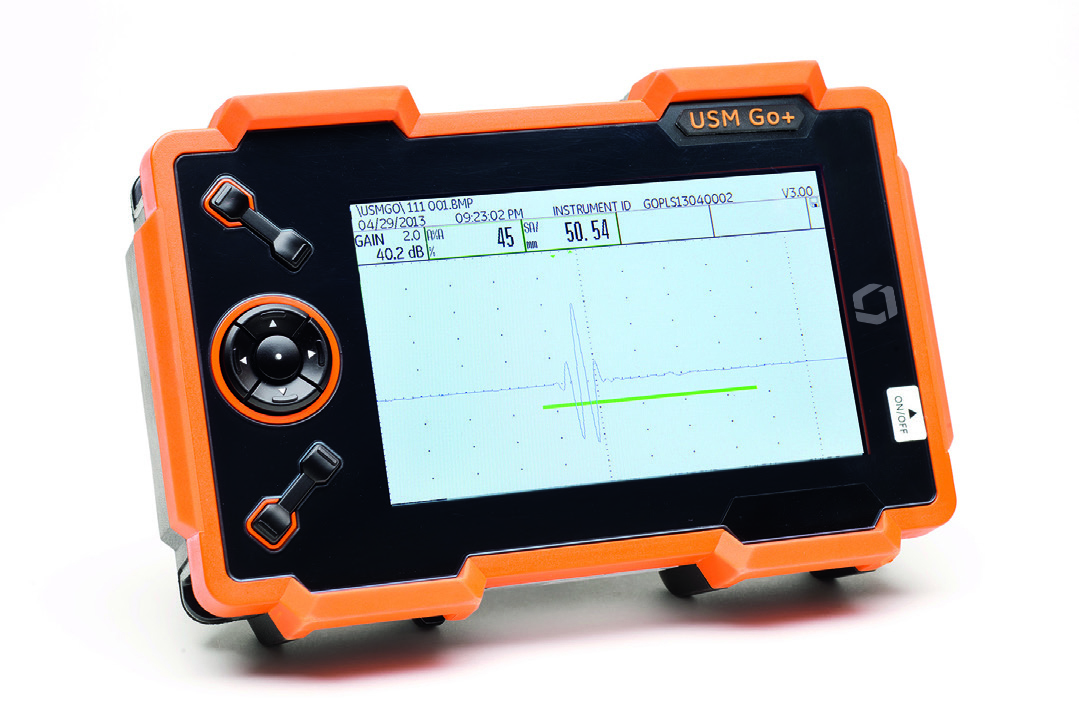

Waygate Krautkramer USM-Go+ Flaw Detector

September 12, 2019

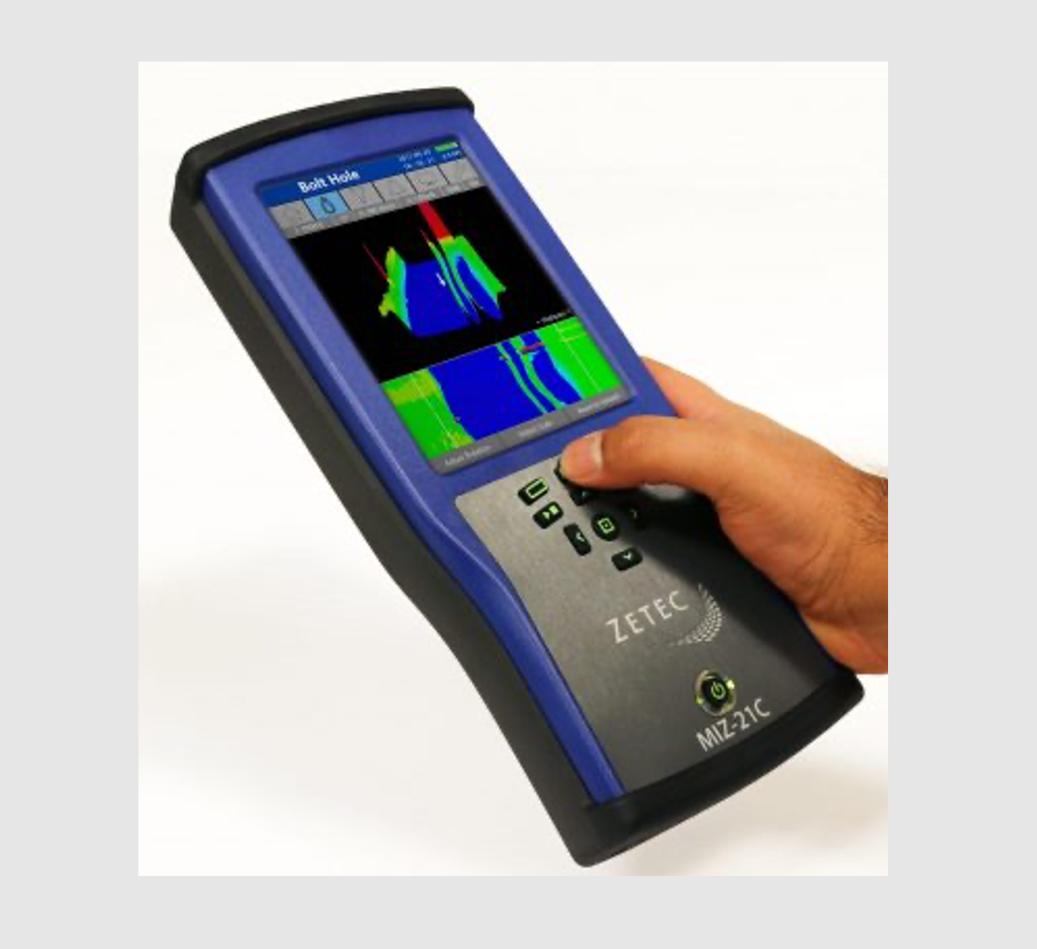

Zetec MIZ-200 Eddy Current Instrument

September 12, 2019Zetec MIZ-21C Eddy Current Instrument

Introducing MIZ®-21C, the most advanced handheld instrument with surface array capabilities. The truly affordable MIZ-21C is ideal for aerospace, oil & gas, manufacturing and power generation applications. Its ergonomic design, long battery life and intuitive touchscreen mean you can inspect more areas faster than ever without fatigue. The MIZ-21C is compatible with a wide range of probes and scanners and comes in three models to meet your unique inspection needs and budget.

Introducing MIZ®-21C, the most advanced handheld instrument with surface array capabilities. The truly affordable MIZ-21C is ideal for aerospace, oil & gas, manufacturing and power generation applications. Its ergonomic design, long battery life and intuitive touchscreen mean you can inspect more areas faster than ever without fatigue. The MIZ-21C is compatible with a wide range of probes and scanners and comes in three models to meet your unique inspection needs and budget.

Details

Designed for a Wide Range of Applications.

MIZ-21C delivers an inspection advantage across numerous inspection applications including:

Detecting Cracks Near Fastener Holes. Pencil probes are ideal for detecting small cracks in close proximity to fastener holes. The inspector uses a known crack or notch standard to set up the MIZ-21C signal display. Then, while scanning the test piece, the inspector can estimate the depth and length of surface cracks by comparing the phase and amplitude of the generated eddy current signal to the standard’s signal.

Multi-Layer Corrosion Inspection. Identifying corrosion is one of the most critical and complex aspects of airframe inspections. Changes in skin thickness as well as varying multi-layer structures usually make it difficult to recognize signals. The MIZ-21C has the power to penetrate thick sections. Exceptional signal-to-noise ratio helps inspectors distinguish even a small loss of material. Dual-frequency with mixing nearly eliminates the unwanted signals caused by varying air gaps between layers that can “mask” the signal of interest.

Conductivity and Coating Thickness Measurement. Use digital conductivity measurements (resistivity) to characterize/ sort materials. Directly measure the conductivity of metals and alloys, such as aluminum structures, using dedicated conductivity probes that have a broad operating frequency range. Or measure a nonconductive coating such as paint. The MIZ21C offers a wide measurement range for both conductivity and thickness.

Save Time & Money.

MIZ-21C is a fast, highly portable and cost-effective replacement for Liquid Penetrant Testing (PT) and Magnetic Particle Testing (MT) inspections. The surface array option can reduce inspection time by up to 95% versus pencil probes. MIZ-21C’s intuitive touchscreen and simple, yet powerful embedded software gets users inspecting in no time, offering quick set-up and hassle-free operation.

Inspect More Areas.

The MIZ-21C is designed for user comfort. It can be held for twice as long as other Eddy Current portable devices. The small form factor enables users to inspect hard-to-reach areas and components that other instruments can’t. MIZ-21C brings the power of surface array to places it has never been before.

Improve Flaw Detection.

MIZ-21C features an industry-leading signal quality providing up to 25% better flaw detection capability. When coupled with surface array, users can be confident that MIZ-21C will deliver the most thorough inspection in its class.

Specifications

| FEATURE | |

| Size (H × W × D) | 267 × 122 × 38 mm (10.5 × 4.8 × 1.5 in) |

| Weight (including batteries and cover) | 1.13 kg (2.5 lb) |

| Multi-Touch Display | 5.7 in (480 x 640 pixels) |

| Battery Life | 8 hr per charge |

| Cooling | Sealed and fanless |

| Eddy Current Connector | 18-Pin Lemo |

| Eddy Current Array Connector | 26-Pin Lemo |

| Connectivity | USB 2.0, Wi-Fi, Bluetooth |

| Encoders | 2 axes, quadrature |

| Probe Recognition and Setup | Automatic, Zetec Coil ID Chip |

| Coil Inputs | MIZ-21C-SF: 1, MIZ-21C: 1, MIZ-21C-ARRAY: 3 |

| Frequencies Per Timeslot | MIZ-21C-SF: 1, MIZ-21C: 2, MIZ-21C-ARRAY: 2 |

| Data Channels | MIZ-21C-SF: 32, MIZ-21C: 64, MIZ-21C-ARRAY: 192 |

| Maximum Probe Coils | MIZ-21C-SF: 2, MIZ-21C: 2, MIZ-21C-ARRAY: 32 |

| Frequency Range | 5 Hz to 10 MHz |

| Generator Output | Up to 19 Vpp |

| Injection Modes | Continuous and Super-Multiplex |

| Receiver Gain | 10 – 53 dB, 43 dB range |

| Data Resolution | 16 bits |

| Acquisition / Sampling Rate | Up to 25,000 per second |

| Probe Drive | 50 Ohm |

| Filters | Adjustable CC, Median, High Pass, Low Pass, Bandpass, Spike |

| Alarms | Adjustable Box, Audio adjustable volume, Headphone support |

| Conductivity Frequency | 60, 120, 240 and 480 kHz |

| Conductivity Specification | Digital readout in 0.9 to 110 %IACS (0.5 to 70 MS/m), Accuracy within ±0.5% IACS from 0.9% to 65% IACS and within ±1.0% of values over 65% |

| Non-Conductive Coating Thickness | Can measure non-conductive coating thickness from 0 mm to

1.000 mm. Accuracy of 0.025 mm (±0.001 in.) over a 0 mm to 0.64 mm range |

| Rotating Scanner | MIZ-21C-SF: No, MIZ-21C: Yes, MIZ-21C-ARRAY: Yes Zetec Rotating Scanner, Others |

| Maximum Data File Size | 60 MB |

| Languages | English, Spanish, French, German, Chinese |

| Storage | 8 GB SSD Internal, Any size through USB expansion |

| Instrument Calibration | Compliant with ISO 15548-1 / EN 61010-1 |

Resources

Zetec MIZ-21C Probe and Accessory Guide

Video – Zetec MIZ-21C Instrument Overview

Video – Zetec MIZ-21C Bolt Hole Demo

Video – Zetec MIZ-21C Array Friction Stir Weld Inspection Demo

Video – Zetec MIZ-21C Array Surface Cracks in Steel Pipes Demo

Video – Zetec MIZ-21C Array Surface Cracks in Train Wheels Demo

Video – Zetec MIZ-21C Array Surface Cracks in Butt Welded Carbon Steel Demo