Clark CPT Series Tester

October 19, 2019

OKOS Scanning Acoustic Microscope Systems

October 19, 2019Waygate SNUP LO/SP Weld Inspection System

The Waygate Krautkramer SNUP System is designed for the inspection of Submerged Arc Welded (SAW) Pipes looking for longitudinal or transverse flaws in the weld seam, laminations in the heat effected zone and laminations or cracks on the pipe ends. The system can be configured for Longitudinal or Helically welded pipes.

The Waygate Krautkramer SNUP System is designed for the inspection of Submerged Arc Welded (SAW) Pipes looking for longitudinal or transverse flaws in the weld seam, laminations in the heat effected zone and laminations or cracks on the pipe ends. The system can be configured for Longitudinal or Helically welded pipes.

Details

Properties and features for both SNUP-LO and SNUP-SP machine types:

- Automated weld seam following by laser tracking of weld seam edges – also for large seam widths (up to 100 mm)

- Online view of weld seam following

- Operation terminal located directly at the test mechanics for quick and easy calibration

- Freely configurable paint marking devices, incl. acoustical and optical indication

- Strip chart visualization and recording of test data

- Automated test report generation

- Stable coupling conditions due to angle beam probes with water gap coupling

- Hardened wear shoes guide the probes on the pipe. These are easy to exchange and offer a long operating life.

- Motorized adjustment of probes: The dataset of ultrasonic parameters also includes the corresponding probe positions. This results in significant shorter changeover times – especially in conjunction with phased array probes.

- Water circulation system with self-cleaning filter or conventional band filter

Phased Array transducers can be used instead of conventional probes, offering additional advantages:

- Higher probability of detection (POD) due to electronic angle optimization

- Lower false call rates due to higher signal to ratio (SNR)

- Improved productivity: Faster setup times for tube dimension change due to fewer mechanical components

- Smaller mechanical dimensions of the overall testing machine

- Electronic beam angle steering offers the potential to meet future testing requirements

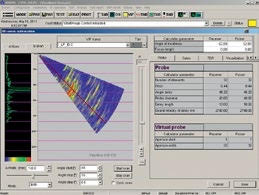

- Sector scan provides easy calibration

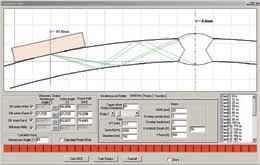

- Visualization of the calculated ultrasonic main beam in the pipe and weld seam

Ultrasonic Testing Machine Electronics Features:

(includes optional items)

- Modular system electronics VIS (conventional) or VPA (Phased Array)

- Easy to operate Microsoft Windows™ GUI

- VME Bus Controller

- Pulse Repetition Frequency 20 kHz max.

- Use of conventional and Phased Array probes with the same VPA electronics

- Double threshold evaluation possible (warning/alarm)

- Extensive monitoring functions, self-test and diagnostic support

- Strip chart for displaying the longitudinal position of the indication

- Automated test report

- Automated transmission of results to a pipe mill server

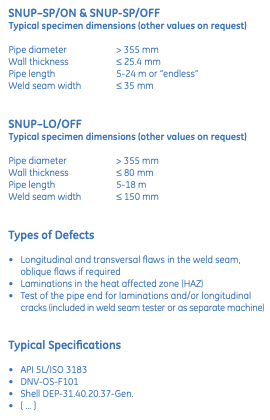

Specifications