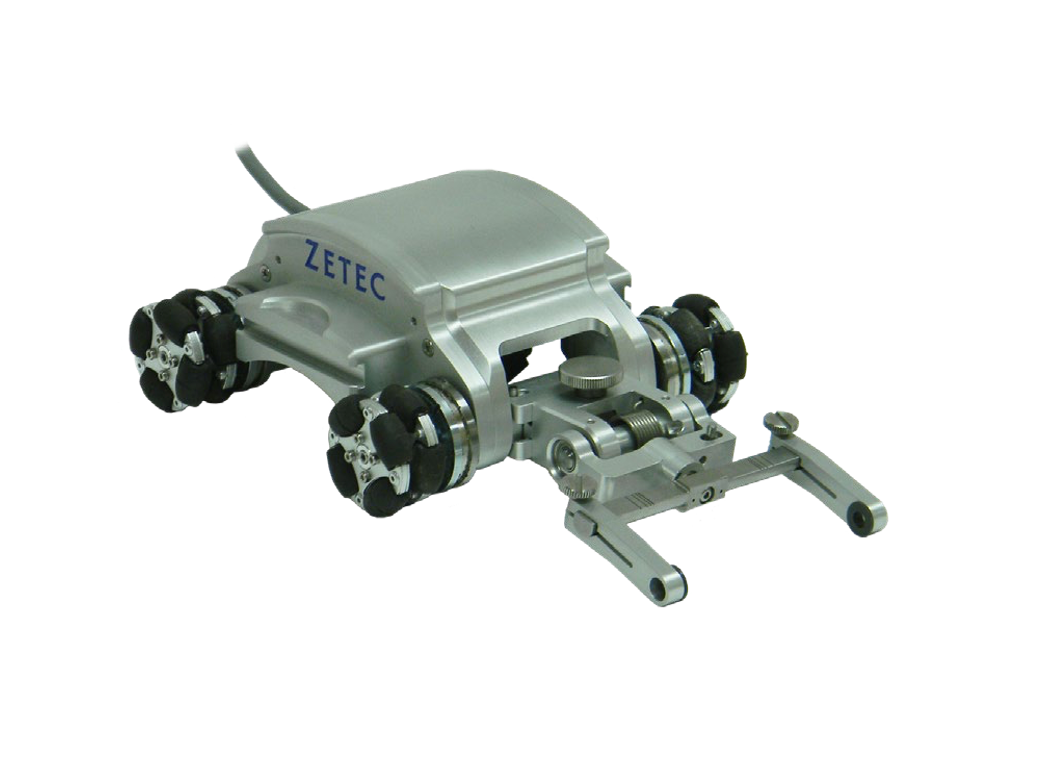

Zetec NDT Sweeper

October 15, 2019

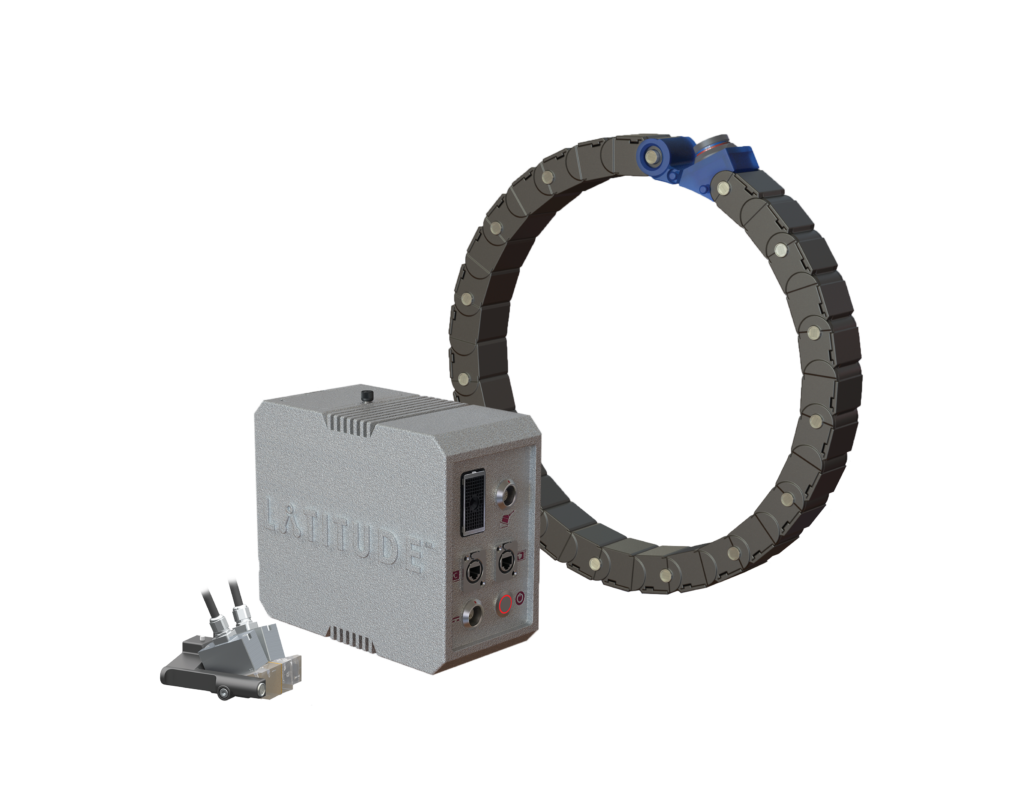

Zetec Latitude Encoding System

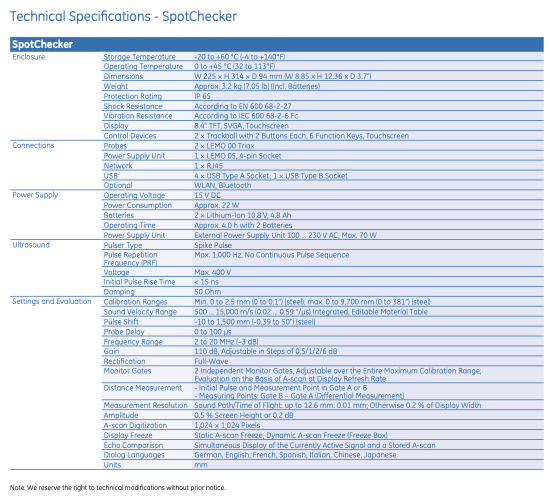

October 15, 2019Waygate Spotchecker Instrument (Discontinued)

The Waygate Spotchecker System is a Ultrasonic Flaw Detection Instrument with Spotweld Specific Inspection Software that allows for fast inspection of spotwelds with automatic weld conditional analysis a data collection.

The Waygate Spotchecker System is a Ultrasonic Flaw Detection Instrument with Spotweld Specific Inspection Software that allows for fast inspection of spotwelds with automatic weld conditional analysis a data collection.

Details

Features and Benefits:

- Portable and Robust – SpotChecker weighs just 3.2 kg (7.05 lb), is battery operated and is sealed to IP65. It features hot swap battery exchange to ensure continuous operation. Battery charging can be done with batteries inside or outside of the instrument, using an external charger. Portability allows inspection to be carried out at the place of welding or on the production line, with no need to transport components to designated inspection stations. As a result, more inspections can be carried out within the same time frame, which means increased productivity.

- Easy-to-Use – SpotChecker does not require intensive training but offers the advantage of an “expert” system for people less qualified in weld inspection. Its ergonomically designed operator interface features an 8.4” LCD touch screen, six programmable function keys and twin track balls, so that it can be operated simply and efficiently in the most restricted of testing locations.

- Connectivity – The flaw detector can be connected to external periphery devices such as mouse, keyboard and printer by USB. The instrument can also be connected to a PC wirelessly by WLAN or Bluetooth for data up-and down-load.

A non-directional, user-friendly remote control, equipped with programmable functions, provides extended flexibility. Intelligent dialog probes, whose data is automatically recognized and loaded, ensure 100-percent documentation accuracy and increased test reliability in spot weld inspection.

- Can be Integrated within Quality Control Loops – By transmitting test results immediately and wirelessly to a suitable database, it is possible to achieve accurate and reliable feedback to adjust welding parameters and correct welding faults and eliminate spotweld defects.

Specifications