Newage CPIT / CPST Tester

October 19, 2019

Screening Eagle Piccolo / Bambino Leeb Instrument

October 19, 2019Newage Indentron Series Rockwell Tester

Using precision dead weights, the Newage Indentron ensures precise, accurate and repeatable measurements. The Indentron is the only Rockwell hardness tester system to use dead weights for both the Preload and Test Load.

SKU: Newage Indentron Series Rockwell Tester

Category: Rockwell Testers

Using precision dead weights, the Newage Indentron ensures precise, accurate and repeatable measurements. The Indentron is the only Rockwell hardness tester system to use dead weights for both the Preload and Test Load.

Details

Features and Benefits:

- Unique Configuration – Cantilevered load arm provides an exceptional view of the indenter and test location. The accurate test positioning prolongs diamond life and enables testing of internal diameters and other tough to measure locations such as shoulders, recesses and grooves.

- Dead Weight Loading – Dead weights ensure high accuracy and long term stability. This significantly reduces wear or improper adjustment. Also the weights in the Indentron are much heavier than competing testers so little mechanical leverage is needed in the loading mechanism.

- Friction Free Operation – The Indentron design is virtually free of the effects of frictional inconsistencies providing exceptional accuracy and repeatability. Also maintenance such as adjustment and lubrication is virtually eliminated.

- Easy Load Setting – Loads are easily selected by a single lever on single range testers and by two levers on combination testers. The electronics monitor the load selection and ensure that the correct load is selected for the Rockwell scale being measured.

- Minimize Measurement Errors – For optimal repeatability and less operator influence, the Test load is automatically applied at correct preload. Application of the Test load is prevented if preload is over or under applied.

- Easy to measure difficult locations – The indenter design makes it ideal for testing inside diameters. Using the standard indenter, inside diameters as small as 1-1/2” can be tested. An optional indenter adapter and shortened indenter can test inside diameters as small as 1/2”. The design provides the operator with an excellent view of the testing location.

- Easy Calibration on All Units – The Indentron is easily and quickly calibrated. Advanced electronics allow all scales to be calibrated independently thus ensuring high accuracy and low cost of ownership.

- Large Measurement Envelope – For long life and easy adjustment the elevating screw runs on ball bearings. The vertical capacity is a full 10” and enables large test specimens to be tested. Extended versions with a capacity of 15” are available on request.

- Simple Operation – Intuitive electronics allow easy scale selection, scale conversion per ASTM-140, roundness correction and HI/LO tolerance selection.

- Data Output for Quality Control – Standard RS232 output of all measured results to Newage’s own DataView quality software, or to other data collection software or devices.

- ASTM E-18 Conformance – The Indentron Series conform to ASTM E-18 and ISO 6508.

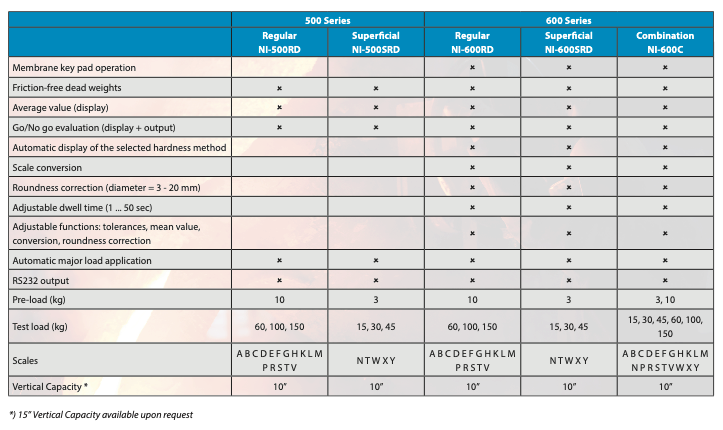

Specifications