Zetec Weld Crawler

October 15, 2019

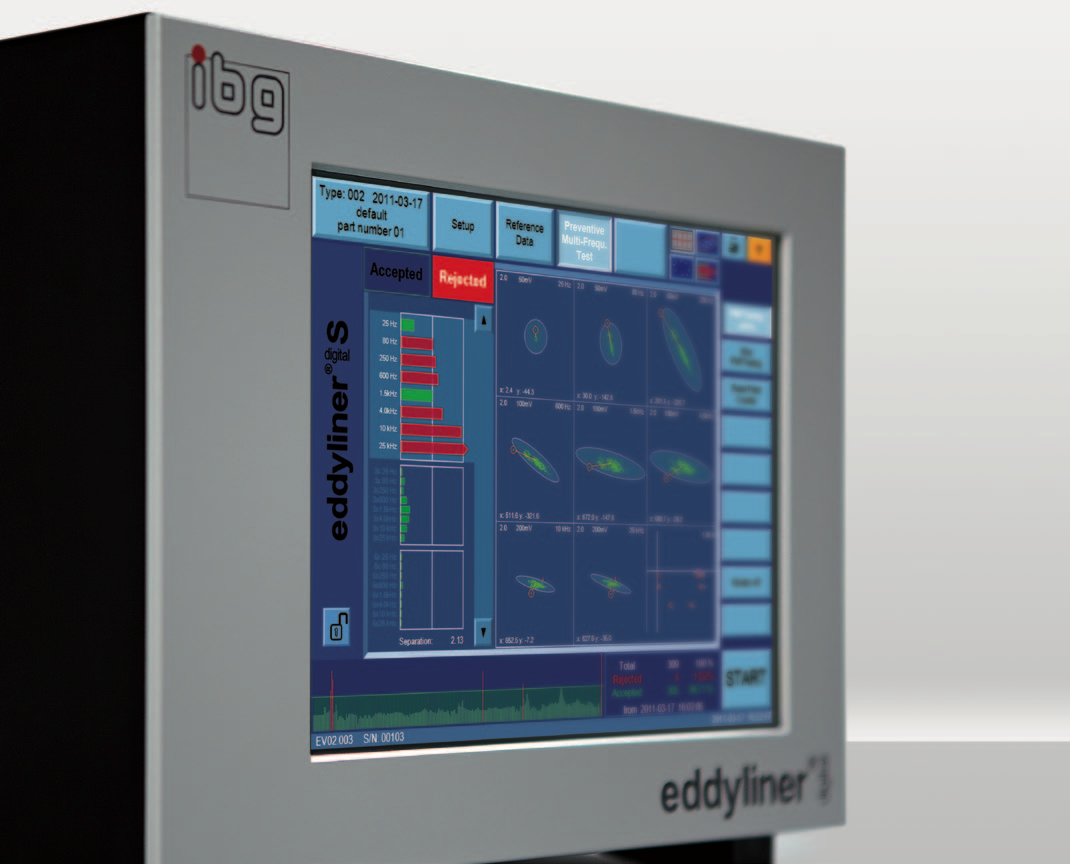

IBG Eddyliner Structure Test Instrument

October 15, 2019IBG Eddyguard Crack Test Instrument

The IBG Eddyguard C Digital Test Instrument is a single channel eddy current test instrument for non-destructive testing of metal components, mass produced parts and semi-finished products according to IBG’s Preventive Multi-Filter Technology (PMFT).

Testing for cracks, pores and grinder burn.

The IBG Eddyguard C Digital Test Instrument is a single channel eddy current test instrument for non-destructive testing of metal components, mass produced parts and semi-finished products according to IBG’s Preventive Multi-Filter Technology (PMFT).

Testing for cracks, pores and grinder burn.

Details

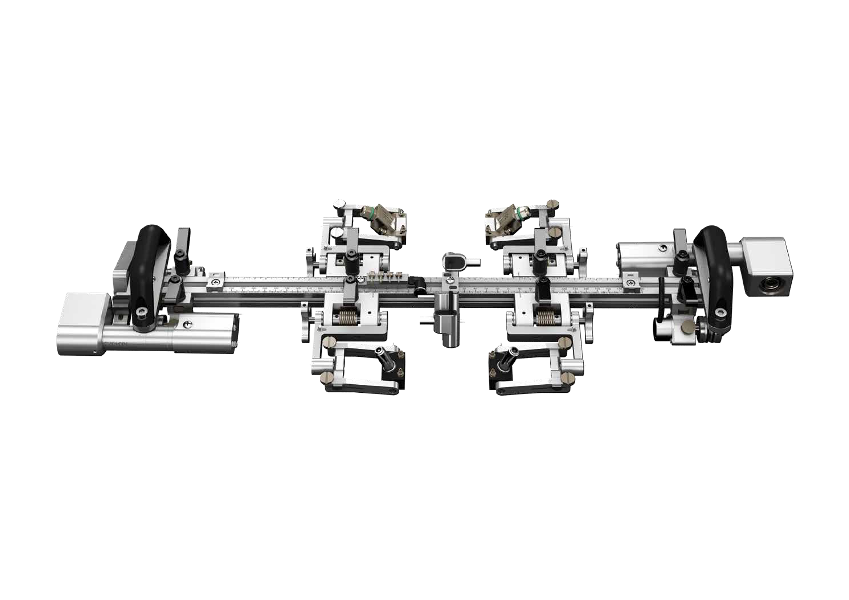

- Probes – A variety of crack detection probes are available with different scan width, sensitivity and design. Customised models for special applications are designed and manufactured in house. Our compact and precision rotating heads eddyscan H and eddyscan F, operated with our eddyguard, can be the solution for cycle time optimised crack tests. Monitoring of probe cable break guarantees maximum reliability for continuous operation.

- Lift-off Compensation – Eccentricity of a workpiece can be offset electronically thanks to the optional lift-off compensation. This function requires special lift-off compensation probes.

- Suspend – The suspend function enables areas on components such as holes not to be tested.

- Part Types – Maximum 20 part types with all settings and reference data can be stored at the same time in the device memory and switched manually via the PC/ laptop or via PLC for automated processes.

- Displays – (with connected PC/laptop only) Test results are shown as bargraph, xy-diagram with tolerance zones, x(t) and y(t) or three-dimensional C-scan, selectable. The C-scan (or cascade diagram) provides a plannar display of a cylindrical surface to enable visualisation of defect position and length.

- Probe Distance – Ibg probes are standard designed for a large distance between probe and test part of 0.7 mm. This considerably widens the scope for the requirements concerning parts preciseness and test mechanic.

- Frequency Range – The carrier frequency is selectable within a range of 3 kHz and 10 MHz in 21 steps. The filter frequencies of the 30 band pass filters are spread in the range 6 Hz – 5 kHz.

- Data Storage – Part types and device settings are stored on the PC/ laptop and can additionally be stored on an USB stick.

- Activating Test – Start of test manually on the PC/laptop, via PLC or an optional start button.

- Automation without PLC – Direct control of sorting devices, paint marking systems or indicating lamps is possible with merely an external voltage source 24Vdc, providing a low cost solution for small automated systems without an additional PLC.

- Operation / Configuration – By means of the delivered ibg operating software to be installed on a PC/laptop supplied by customer. System requirements: USB 2.0 and operating system MS Windows 7 (32 or 64 bit) or Windows XP (32 bit).

- Help Function – The software for the PC/laptop has a context sensitive help function which often renders a look into the manual unnecessary.

- Languages – The software for the PC/laptop may be set to German, English, French, Spanish, Italian, Czech, Portuguese, Hungary, Polish, Chinese, Japanese, Korean and Russian. Other languages as option.

Specifications

Connections

- IO-Ports optically insulated interface for PLC connection with 32 inputs and 32 outputs

- USB 2.0 for connection of a PC/Laptop supplied by customer

Housing

- Completely sealed and thus can be used in a dusty production environment

- For installation on top hat rail TH35 as per DIN EN 60715.

Technical Data

- Mains: 100 – 240 V, 50/60 Hz

- Protection class: IP 41

- Ambient temperature: 0 – 45°C

- Relative humidity: max. 85 %, non condensing

- Dimensions (w x h x d): 239 x 165 x 169 mm Weight: 4 kg

Documentation

Videos

Video – IBG Eddyrobot Crack and Grinder Burn Detection on Flanged Inner Rings

Video – IBG Crack and Grinder Burn Detection on Bearing Rings Inner Radius and Outer Radius

Video – IBG Crack and Grinder Burn Detection on Large Rings

Video – IBG Ringtester, Crack Test on Inner and Outer Diameters

Video – IBG Crack, Structure, Gauging and Visual Inspection of Pinion Shafts

Video – IBG Crack and Structure Test on Cylinder Liners

Video – IBG Crack, Grinder Burn and Structure Test on Ball Nuts

Video – IBG Crack Detection on Pins

Video – IBG Crack and Structure Test on Lobes for Assembled Camshafts